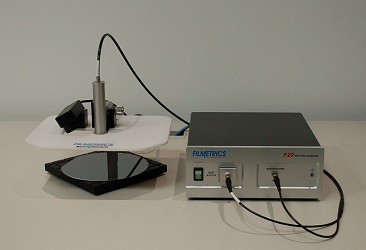

F20 with standard spot and reflection probe

Amorphous Silicon (a-Si) and Poly Silicon Thickness Measurement

Elemental silicon can exist in amorphous and crystalline forms, and in between these two extremes as partially-crystallized silicon. The partially-crystallized form of silicon has a variety of names and may be referred to as polycrystalline silicon, polysilicon, poly-Si, multicrystalline silicon, or mc-Si.

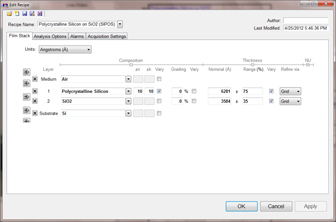

The optical constants (n and k) of amorphous and polysilicon are unique to the deposition conditions and must be measured for an accurate thickness measurement. Roughness and possible grading of the silicon film crystallinity must also be taken into account and be measured along with thickness.

Filmetrics® instruments include sophisticated measurement routines that simultaneously measure and report each of the required silicon film parameters, all with a single mouse-click.

Contact our thin-film experts to discuss your amorphous polysilicon application.

Filmetrics offers free trial measurements - results are typically available in 1-2 days

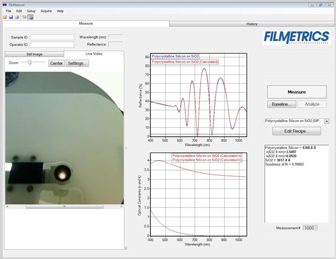

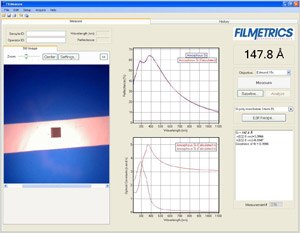

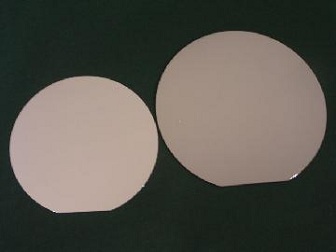

Thickness Measurement Example

Polysilicon is a widely used material for silicon-based electronic devices. The efficiency of these devices depends on the optical and structural properties of the film. These properties change with the change in deposition and annealing conditions so it’s important to accurately measure these parameters. The thickness and optical properties are measured on monitor wafers which have an SiO2 interlayer to increase the optical contrast between the silicon substrate and polysilicon film. The thickness and optical properties of polysilicon films and the thickness of SiO2 interlayer can be easily measured with Filmetrics F20. The Bruggeman optical model was used to measure the optical properties of polysilicon film.