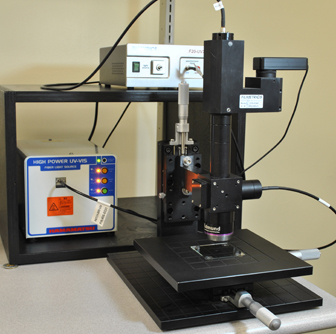

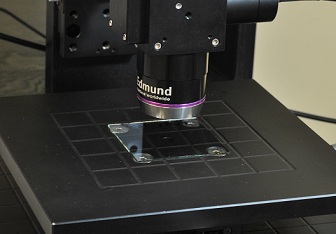

F40-UV with a 250µm aperture

OLED Metrology: OLED Display Thickness Measurement

Organic Light-Emitting Diodes (OLEDs)

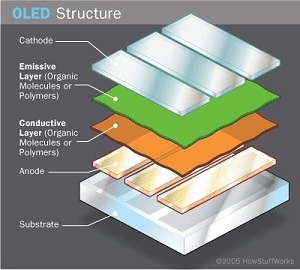

OLEDs are rapidly moving from the research lab to the fab. Their bright, ultra-thin, and dynamic characteristics make them appealing for many display applications, ranging from cell phones to TVs. The metrology of the many thin films that make up OLED displays is of critical importance, and too critical to be entrusted to traditional contact profilometry which can damage these relatively soft layers. Our F20-UV, F40-UV film thickness measurement instruments and F10-RT-UV reflectometer instruments offer inexpensive, robust, and non-invasive metrology of simple prototype devices and fully-pixelated displays. Because our OLED measurement instruments are spectroscopic, one can also detect chemical changes that can occur in these atmospherically-sensitive materials.

Measure Transparent Conductive Oxides

Whether one encounters Indium Tin Oxide, Zinc Oxide, or Poly(3,4-ethylenedioxythiophene) in OLED films, our proprietary ITO optical model, coupled with our visible/near IR instruments, can solve for both thickness and optical constants at a fraction of the cost and effort of a spectroscopic ellipsometer.

Measure Complicated Organic Materials

A typical OLED requires a number of specialized film layers: Hole Injection Layers, Hole Transport Layers, and Recombination/Emission layers. All these OLED film layers contain unusual organic molecules (either small molecule and/or polymers). Dealing with such materials could be a challenge for spectral reflectance due to their highly-anomalous optical dispersion but not for Filmetrics®. Our materials database stretches back to the very beginnings of OLED and can deal with the high index dispersion and multiple UV features encountered with these molecules.

Measurement of Films on Flexible Substrates

OLEDs offer the promise of enabling truly flexible displays. This requires measurement on highly birefringence substrates such as PET. This poses a serious problem for metrologies such as ellipsometry: one must either model this additional optical complication or sandpaper the PET’s backside. Neither of these approaches are required for our unpolarized spectral reflectance. This yields significant time savings for both user training and measurement cycle time.

OLED Measurements Inside a Glove Box

OLED film materials are extremely sensitive to water and oxygen. Many research groups require OLED thickness measurements inside the controlled atmosphere of a dry N2 glove box. The small form factor of our instruments and their modular, fiber-optic-based design easily allows real time “in-the-box” measurements of unencapsulated devices.

Filmetrics offers free trials of thickness measurements of OLED film samples, with results typically available in 1-2 days. Contact our thin-film experts to discuss your display material and OLED measurement application.

OLED Thickness Measurement Example

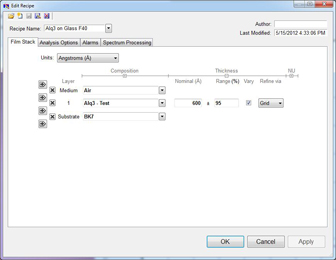

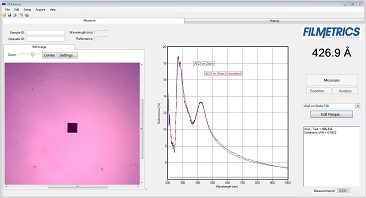

In this example we show an OLED film thickness measurement of AlQ3 on glass. Filmetrics instruments can easily measure the thickness of such organic materials including their complicated optical behavior in the UV region. Not only does this provide a non-destructive method (as compared to contact profilometry) to measure OLED film thickness, but also allows the user to observe chemical changes in such OLED films. This high resolution result was obtained on a 17µm spot size F40-UV instrument. This spectrum corresponds to the area within the black square shown in the video image. Measuring multiple OLED films within a single pixel is now possible with such a setup.