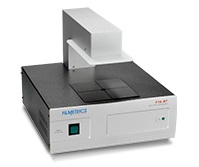

F10-RT

Metal Thickness Measurements

Metal thin films find diverse applications across a wide spectrum of industries. Metal thin films play a pivotal role in such industries as medical device manufacturing, aerospace industry, home goods, jewelry, semiconductor industries, and so many more. Ensuring quality control over metal thin film coatings is critical and essential for manufacturers. Filmetrics® offers a range of precise measurement solutions for assessing metal film thickness:

Profilometry

An Easy Method for the Measurement of Metal Thickness

Profilometry is a common and easily applicable method for metal film thickness measurements. All that is needed is a step from an uncoated to a metal-coated area to determine the step height and therewith the metal thickness. With profilometry, there is little need to know specifics about the material under investigation, and the maximum measurable thickness is only restricted by the maximum measurable thickness of the optical profiler used. The step-height accuracy in profilometry depends on the vertical resolution of the profiler. In the case of the Filmetrics Profilm3D® optical profilometer, the accuracy is 0.7% for an 8 µm step – which means 56 nm!

Spectral Transmittance (ST)

Metal Thickness Measurement for Very Thin Metal FilmsFor very thin metal films, spectral transmittance (ST) measurements are an alternative and less expensive way to measure metal film thickness. For this kind of metal thickness measurement, Filmetrics offers the F10-T. For ST measurements, the maximum measureable thickness depends strongly on the metal at hand (see table). However, there are a few limitations to this approach of metal thin film thickness analysis. For one, the substrate material must be transparent. For another, the optical constants of the material under investigation must be known to get accurate results. Often, this is uncritical because Filmetrics provides a large database of material data files with its instruments. If, on the other hand, the material’s properties are unknown or changing on a regular basis (e.g. if coating process parameters are changed occasionally), the sole measurement of ST is not enough. In this case, the following approach of combined spectral transmittance and spectral reflectance is more suited.

Combination of Spectral Transmittance and Spectral Reflectance (ST/SR)

Metal Thickness Measurements of Materials with Unknown Optical Properties

If the optical properties of the material are unknown, a simultaneous measurement of spectral transmittance and reflectance can be used to determine the optical constants and to measure the film’s thickness in the same process. In this case, the measurable thickness range is about half of ST measurements. The instrument of choice for this is Filmetrics’ F10-RT reflectometer, which is priced about the same as our Profilm3D optical profiler.

Summary of the Three Metal Thickness Measurement Methods:

| STYLUS PROFILOMETRY | ST | ST/SR | |

|---|---|---|---|

| Suitable Instruments | Profilm3D | F10-RT | F10-RT |

| Thickness Range | 50nm-10mm | see table below | contact us |

| Material optical properties required? | No | Yes | No |

| Transparent substrate required? | No | Yes | Yes |

Examples of Maximum Measurable Thickness Using Spectral Transmittance:

| Metal | Maximum Measurable Thickness by Transmittance | Approx. %T Peak Position |

|---|---|---|

| Ag (Silver) | 360nm | 320nm |

| Al (Aluminium) | 53nm | 900nm |

| Au (Gold) | 200nm | 500nm |

| Cu (Copper) | 135nm | 575nm |

| Nb (Niobium) | 135nm | 750nm |

| Ti (Titanium) | 260nm | 1700nm |

| W (Tungsten) | 133nm | 1500nm |

Metal Thin Film Thickness Measurement Example

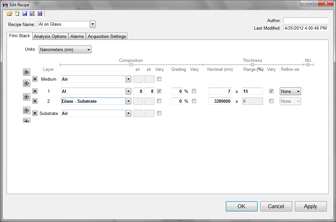

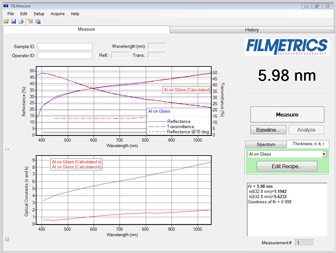

This particular sample was a thin film of aluminum on a glass substrate. In order to solve for thickness as well as optical constants, measurements were taken on our F10-RT system, which combines reflectance and transmittance at normal incidence. Through the use of our “No Model” model, we measured the thickness and optical constants of this metal film, all with a single mouse-click.