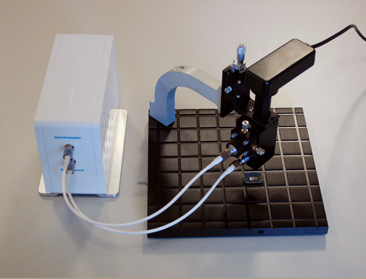

F3-s1550 with SampleCam-sX

Integrated Circuit (IC) Failure Analysis

Today, the reliability of ICs in electronic devices and finding the root cause of performance issues is critical. Failure Analysis (FA) techniques are used to locate and identify the cause of failure in integrated circuits (IC). Filmetrics supplies instruments for your IC failure analysis procedures.

The two main types of IC Failure Analysis applications that require film thickness measurement are front side delayering (for traditional device-side up circuit packaging) and backside thinning (for the newer flip-chip device-side down circuit packaging.)

IC Failure Anlaysis in Front Side Delayering

The front side delayering process examines an IC failure through removal of material on the front side of the chip to expose the root cause of the failure with analysis of the defect within the chip's internal layers. This process requires knowledge of the thickness of the dielectric remaining after dielectric thinning. The Filmetrics® F40 microscope-based film thickness measurement instrument is ideal for this IC failure analysis application.

Backside IC Failure Analysis

Backside IC FA requires removing most of the Si die thickness before the circuitry can be imaged and knowing the thickness of the remaining Si after each thinning step is critical. The Filmetrics F3-sX system was designed specifically to take on the challenge of measuring the thickness of rough Si layers resulting from various backside thinning processes. Thicknesses from 5µm to 1000µm are easily measured. An option is available that extends the minimum measurable thickness down to under 0.1µm. Both single spot and mapping versions are also available.

Contact our thin-film experts to discuss your dielectric application.

Filmetrics offers free trial measurements - results are typically available in 1-2 days

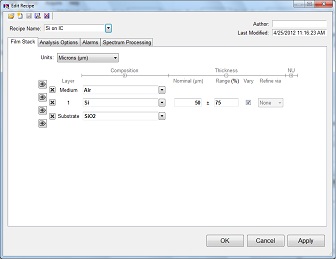

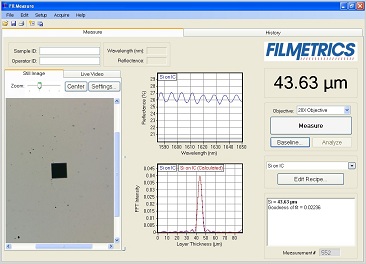

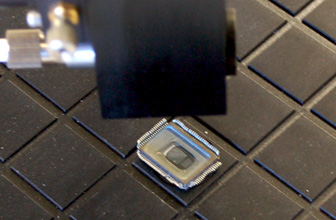

IC Failure Analysis Thickness Measurement Example

Here we use our F3-s1550 system to measure the thickness of remaining Si on an integrated circuit after backside thinning. The F3-s1550 utilizes special optics which produces a spot size less than 10μm in diameter, allowing for the measurement of polished as well as rough and non-uniform layers.