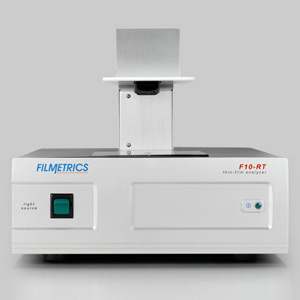

F10-RT-EXR

Thickness Measurement of Indium Tin Oxide (ITO) and Other Transparent Conductive Oxides (TCOs)

Liquid-crystal displays, the multitude of organic light-emitting diode (OLED) variants, and most other flat-panel display technologies rely on transparent conductive oxide (TCOs) thin-films such as indium tin oxide (ITO) to transport current and to serve as the anode for each light-emitting element.

Knowing the thickness of the layers of ITO film and other TCO films that form the display is an important advantage in any thin-film process. For LCDs, determining thickness requires a way to measure the polyimide and liquid-crystal layers in addition to measuring the film thickness of the ITO layer. For OLEDs, a thickness measurement must examine the emitting, injecting, and encapsulation layers.

In measuring any multilayer stack, optical techniques such as spectral reflectance and ellipsometry require the thickness and optical constants (refractive index and k) of every layer in the stack to be either measured or accurately modeled.

ITO film layer thickness and other transparent conductive oxide thin films thickness measurements in displays is important for reasons including:

- Electrical Conductivity

- Optical Transparency

- Manufacturing Control

- Cost Efficiency

When that stack contains an ITO film layer, it becomes more challenging to measure and model the other layers. This is because Indium Tin Oxide has a unique spectral signal that generally dominates the other layers. The refractive index of the ITO film layer must be measured accurately in order to then determine the thickness of the other material layers.

In addition, an accurate refractive index measurement of the ITO layer is important to confirm that the compound used will deliver the right level of conductivity, or to verify the thickness of an ITO film that is built into display glass.

The Filmetrics® Solution for Measuring ITO Film Thickness

The Filmetrics F20-EXR film thickness measurement instrument uses spectral reflectance to deliver a simple and affordable solution for accurate ITO film thickness measurements. This transparent conductive oxide thickness measurement solution combines a new ITO dispersion model with the wide 400-1700nm wavelength range of the F20-EXR to provide robust, "one-click" analysis of ITO thickness. Once the ITO layer is characterized, the F20-EXR can analyze the remaining display layers.

Whether you are involved in basic research or display manufacturing, Filmetrics can deliver the capabilities you need to measure, including the following.

Liquid crystal layers- Polyimide, hardcoat, and liquid crystal thickness

- Emission, injection, buffer, and encapsulation

For non-patterned samples, consider the Filmetrics F20 family of film-measurement instruments. For patterned films, the Filmetrics F40 for measuring film thickness has found wide use in display applications.

Filmetrics offers free trial measurements of ITO film and other TCO film samples, with results typically available in 1-2 days. Contact our thin-film experts to discuss your display material and TCO measurement application.

ITO Film Thickness Measurement Example

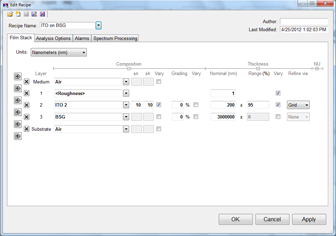

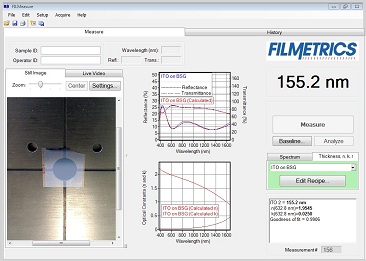

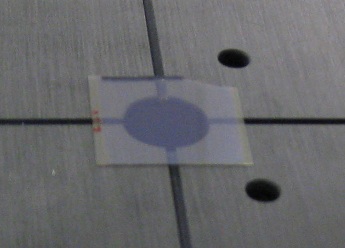

In this example, we successfully measure an ITO film deposited on borosilicate glass (BSG). By using the F10-RT-EXR reflectometer in conjunction with Filmetrics’ proprietary ITO dispersion model, one can easily determine the thickness, refractive index, and extinction coefficient of ITO by simultaneously measuring the transmittance and reflectance between 380-1700nm. This extended wavelength range is necessary due to the unusual dispersion seen from ITO films. With the F10-RT-EXR, ITO film thickness can also be measured on a variety of substrates including silicon, sapphire, glass, or polymers.